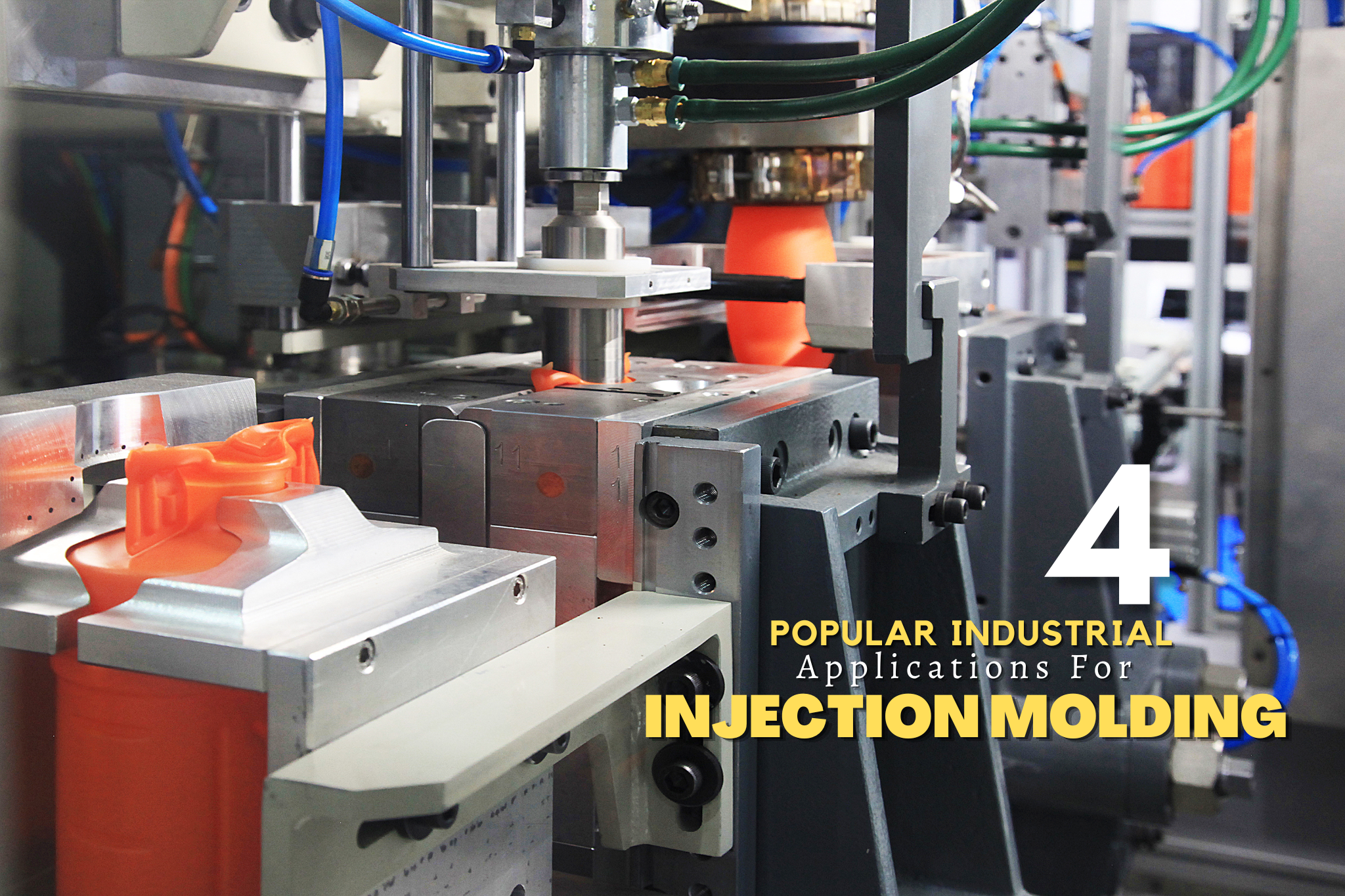

For most industries, the main motto is to find out the lowest cost yet most durable materials to produce the products they need. As a flexible manufacturing method, injection moulding plays a vital role in developing and producing many modern products. This blog brought to you by one of the most reputed injection moulding machine distributors in the Philippines will look at the top 4industrial applications for injection moulding.

Food and beverages:

The food and beverage industries vividly depend on injection moulding. This industry largely relies on plastic materials to create product packaging and containers for various foods and beverages. From certain elements as tiny as bottle caps to the trays used in TV dinners, the injection moulding method provides a one-stop solution for all the food and beverage industry’s packaging and container requirements.

Household accessories:

Just with a short trip to your kitchen, you will be able to find an ample amount of injection moulded products. There is not a single chance to deny that this industry would not be where it is today without the help of the injection moulding process. Like many other industries, household accessories can be made more affordable by investing in big production runs for shipping to retail locations globally.

Electronics industry:

A majority of people consider electronic elements as predominately metal piece of machinery that typically requires electricity to perform. However, manufacturing housings through plastic injection moulding processes are highly preferred nowadays. For an instance, the computer mouse you are using right now, or the TV in your drawing room, certainly have some components created using a plastic injection moulding process.

Agriculture industry:

Did you know that the agriculture industry was more likely to invest in metal-made components in the past days simply because they used to provide a durable solution? But nowadays, reinforced plastic options have gained popularity and preference due to new plastic material characteristics like UV-resistance, impact-resistance, humidity resistance, and many more. The capability to create durable agriculture components that usually stand up to the elements on a farm makes the plastic injection moulding method a palpable fit for the agriculture industry, for example, from feeding troughs to specialized harvesting elements.

We expect that this blog has helped you to recognize the industries where injection moulding can be applied. For more informative data, visit ZHH Metals, one of the most recommended injection moulding machine distributors in the Philippines.